The rigid heddle loom has gained considerable popularity in recent years due to it's affordability, portability and versatility as a weaving loom.

The rigid heddle loom is essentially a rectangular, wooden frame loom. However, it differs from the simple frame looms that are now readily available and often used for simple tapestry, as it has a space for a heddle/reed, making it capable of producing sheds (gaps or spaces) to weave through. It is a 2 shaft loom, but has further reaching capabilities, which I will explain further in a future post. I guess you could say that it is a crossover between a simple frame loom and a table/floor loom once you start looking at the specifics.

The "rigid heddle" that the loom gets it's name from is an ingenious device made from wood and often plastic nowadays. A single heddle/reed gives your loom holes and slots (these are what allow you to create the sheds) plus it doubles as a beater. The more of these heddles/reeds you use, the greater the possibility and range of sheds, and therefore patterns, become available. Another benefit of using 2 heddle/reeds at a time is the ability to weave double width cloth, which is ultra cool and can be seen in my Double Weave Baby Blanket class. Some rigid heddle looms now come with a built in double heddle block, which means it is easy to have 2 heddle/reeds positioned on your loom.

In it's most basic, 2 shaft form, you place the heddle/reed in either an up or down position, creating a different shed each time. Using these 2 sheds will give you plain weave.

This same heddle/reed will have a predetermined size or sett, which means that once you have established the sett for your project, you choose a heddle/reed that matches. As you thread the heddle/reed, the rigid plastic slots keep the threads at a certain spacing, and that is what makes your sett.

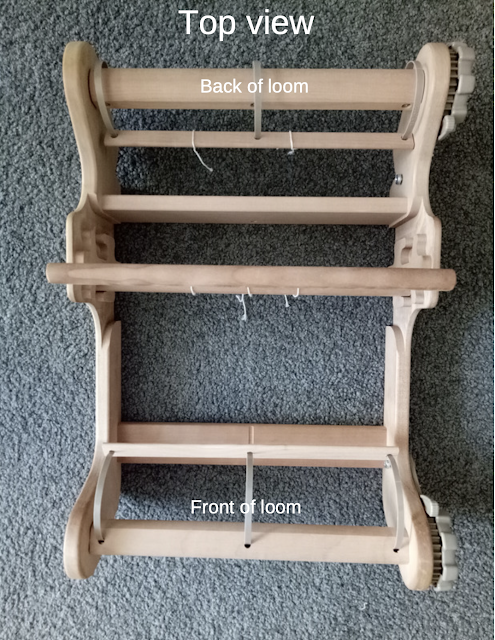

The RHL, similar to table/floor looms, has a front and back roller, meaning that you can put on a long warp and you advance the warp as you go so that the cloth will roll around the front beam as you weave. Some looms will have the option of buying an additional warp beam that attaches to the loom and allows you to put on extra long warps. It also has a tensioning system, which varies from loom to loom, but usually involves winding a pawl or a crank at the side of the loom to achieve good tension.

In addition to your loom, you can purchase a stand, which, in my opinion is a really good option. I talk more about that in this video.

If you purchase a RHL new, it will come with everything you need to get started (except the yarn!)

I hope this has helped you to begin to wrap your head around what a rigid heddle loom is. Next time I'll be discussing what tools you need and how they work, so stayed tuned for that one!

The rigid heddle loom is essentially a rectangular, wooden frame loom. However, it differs from the simple frame looms that are now readily available and often used for simple tapestry, as it has a space for a heddle/reed, making it capable of producing sheds (gaps or spaces) to weave through. It is a 2 shaft loom, but has further reaching capabilities, which I will explain further in a future post. I guess you could say that it is a crossover between a simple frame loom and a table/floor loom once you start looking at the specifics.

The "rigid heddle" that the loom gets it's name from is an ingenious device made from wood and often plastic nowadays. A single heddle/reed gives your loom holes and slots (these are what allow you to create the sheds) plus it doubles as a beater. The more of these heddles/reeds you use, the greater the possibility and range of sheds, and therefore patterns, become available. Another benefit of using 2 heddle/reeds at a time is the ability to weave double width cloth, which is ultra cool and can be seen in my Double Weave Baby Blanket class. Some rigid heddle looms now come with a built in double heddle block, which means it is easy to have 2 heddle/reeds positioned on your loom.

In it's most basic, 2 shaft form, you place the heddle/reed in either an up or down position, creating a different shed each time. Using these 2 sheds will give you plain weave.

This same heddle/reed will have a predetermined size or sett, which means that once you have established the sett for your project, you choose a heddle/reed that matches. As you thread the heddle/reed, the rigid plastic slots keep the threads at a certain spacing, and that is what makes your sett.

The RHL, similar to table/floor looms, has a front and back roller, meaning that you can put on a long warp and you advance the warp as you go so that the cloth will roll around the front beam as you weave. Some looms will have the option of buying an additional warp beam that attaches to the loom and allows you to put on extra long warps. It also has a tensioning system, which varies from loom to loom, but usually involves winding a pawl or a crank at the side of the loom to achieve good tension.

In addition to your loom, you can purchase a stand, which, in my opinion is a really good option. I talk more about that in this video.

If you purchase a RHL new, it will come with everything you need to get started (except the yarn!)

I hope this has helped you to begin to wrap your head around what a rigid heddle loom is. Next time I'll be discussing what tools you need and how they work, so stayed tuned for that one!

5 comments:

What a great opportunity to go ‘back to basics’ as we head towards a new year and a fresh page for weaving.

What a beautiful blog about the RHL. I started with one two years ago, but now I have a bigger loom so the RHL is standing in a corner. But now I am thinking perhaps I should give her more attention😊

Can I ask you a question about a floorloom?

My husband has extend my tableloom to a 'floorloom' with threadles. When you are dressing the loom, at whitch moment you put the 'strings' on the threadles? After you put the warp on the loom or before? Or is it not that important? Thanks in advance! 🌷

I'm glad you think so, Andrea 😊

Marjan, I always thread, sley the reed, tie the warp on and then do my treadle tie up. It seems to make sense in that order. Also, I like to have some treadles out of the way while I'm threading, that way I can get closer to the loom which helps my back.

Thank you Kelly. Especially that last point about the treadles out of the way is handy! 🌷

Post a Comment